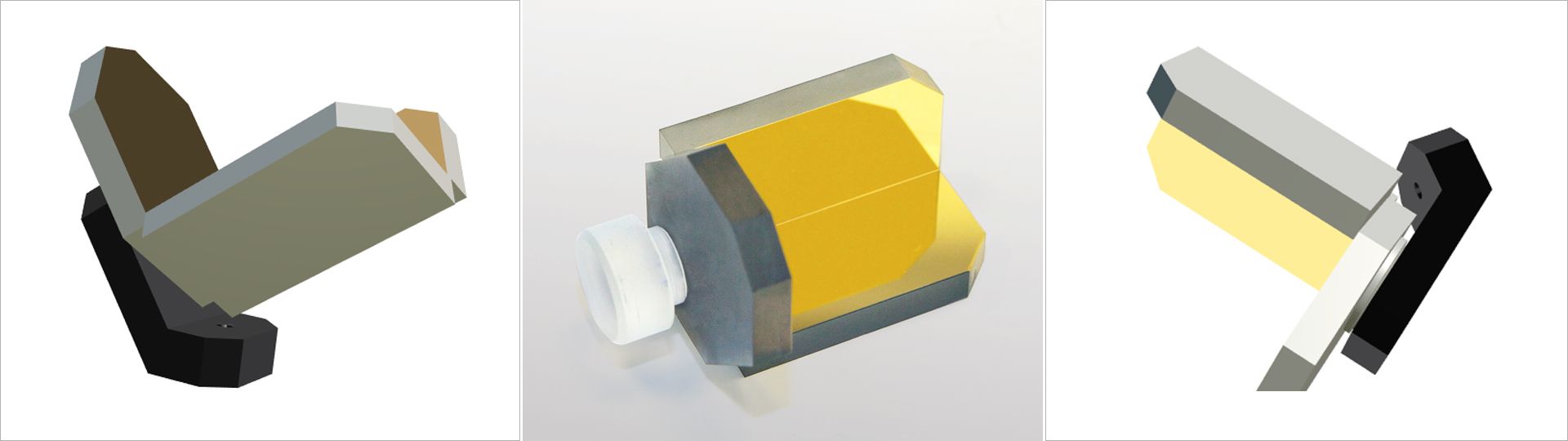

LOW PROFILE RETROREFLECTORS (LPR)

- Exceptional mechanical stability and accuracy due to monolithic construction.

- For critical applications such as Michelson interferometers.

- Compact design for critical OEM applications.

- Self-compensating mirror configuration with excellent beam return accuracy.

- Can be mounted in any orientation via integral post.

- Mirrors can be coated for maximization over any spectral range, from UV to far IR.

- Vacuum compatible.

- Versions tested to withstand military and harsh space environments.

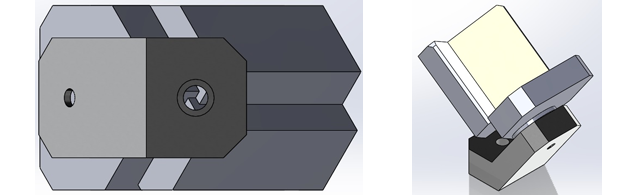

- Custom "Knife Edge" design option available upon request, enhances beam quality, eliminates the cause of obscuration.

- RoHS Compliant.

Hollow Retroreflectors

- All Metal Hollow Retroreflectors™

- Ultra Low-Profile Retroreflectors™

- Hard-Mounted Hollow Retroreflectors™

- Ultra stable Hard-Mounted Hollow Retroreflectors™

- Low Profile Retroreflectors

- Omni Wave Hollow Retroreflectors™

- Tool Cube

- Ball Mounted Hollow Retroreflectors

Related Products:

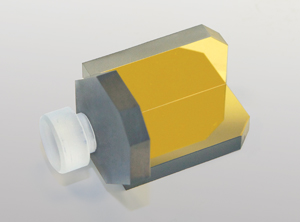

LPR-Series Low Profile Retroreflectors may also find use in laser delay lines and other systems in which optical path difference control is critical, and the input and output beams are distinct and non-overlapping.

Hollow retroreflector input and output beams are parallel, regardless of physical orientation. This dramatically relaxes tilt stability requirements in any extended optical system. In the application of optical path difference control, the user only has to control the position of a single point, the vertex of the retroreflector. Because all rays have the same optical path difference, this variable is easily controlled with a simple laser interferometer sharing a small portion of the clear aperture of the system.

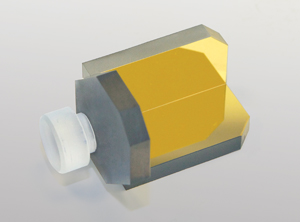

All LPR-Series retroreflectors have compact apertures corresponding to side-by-side input and output beams. They are vacuum compatible, and being hollow retroreflectors, are lightweight and do not suffer from material dispersion, aberration, and absorption effects. Please see the table for specifications and the diagrams for mounting information. Custom Low Profile Retroreflectors are available with short lead times.

Stability and Accuracy

The LPR-Series offers optical properties making it especially suitable for critical applications such as Michelson Interferometers. The integral post permits mounting the retroreflector so that the apex location is accurately known and stable over operating conditions. The LPR is constructed from three first-surface mirrors assembled by a proprietary process into a mutually orthogonal inside corner. The resulting assembly is extremely rugged. The mirrors can be coated for maximization over any spectral range from UV to far IR. The integral mounting post is of the same material as the mirror panels. It is mounted by a clamp via hoop stress. By controlling this clamping force, no distortion is transmitted to the optical assembly, yet the position of the retroreflector is controlled precisely.

Coatings

Standard LPR mirror coatings are aluminum, silver and gold, in both bare metal and with protective overcoatings. All protected coatings meet MIL-SPEC durability and adhesion requirements. Unprotected metallic coatings are especially suited to interferometric applications. Custom coatings are available.

Custom configurations for specialized applications

PLX engineers can create custom hollow retroreflectors for your application. Potential variations include smaller and larger apertures, modified hard mounts to meet your interface, super-critical accuracies, and dielectric mirror coatings for use with high power lasers. The post can be shifted to the roof section. The single flat panel can be polished on the reverse side, and coated to act as a beamsplitter. A variety of proven clamp designs are available to ease mounting design.

If you don't see what you need above:

Click here for a Custom Quote, specify what your application is and our engineering staff will get back to you.